How to Choose the Best Roll Bar or Roll Cage

S&W Performance Group Roll Cages are designed to meet and exceed NHRA, IHRA and most major road races, SCCA and off-road organizations requirements for material size & thickness, but must be installed in accordance with sanctioning bodies guidelines and rules.

They are designed to comfortably fit with your stock interior in place. If you desire a custom tailored fit, our team will bend a custom cage to your measurements.

S&W Performance Group roll bars & roll cages perform both a safety and performance function.

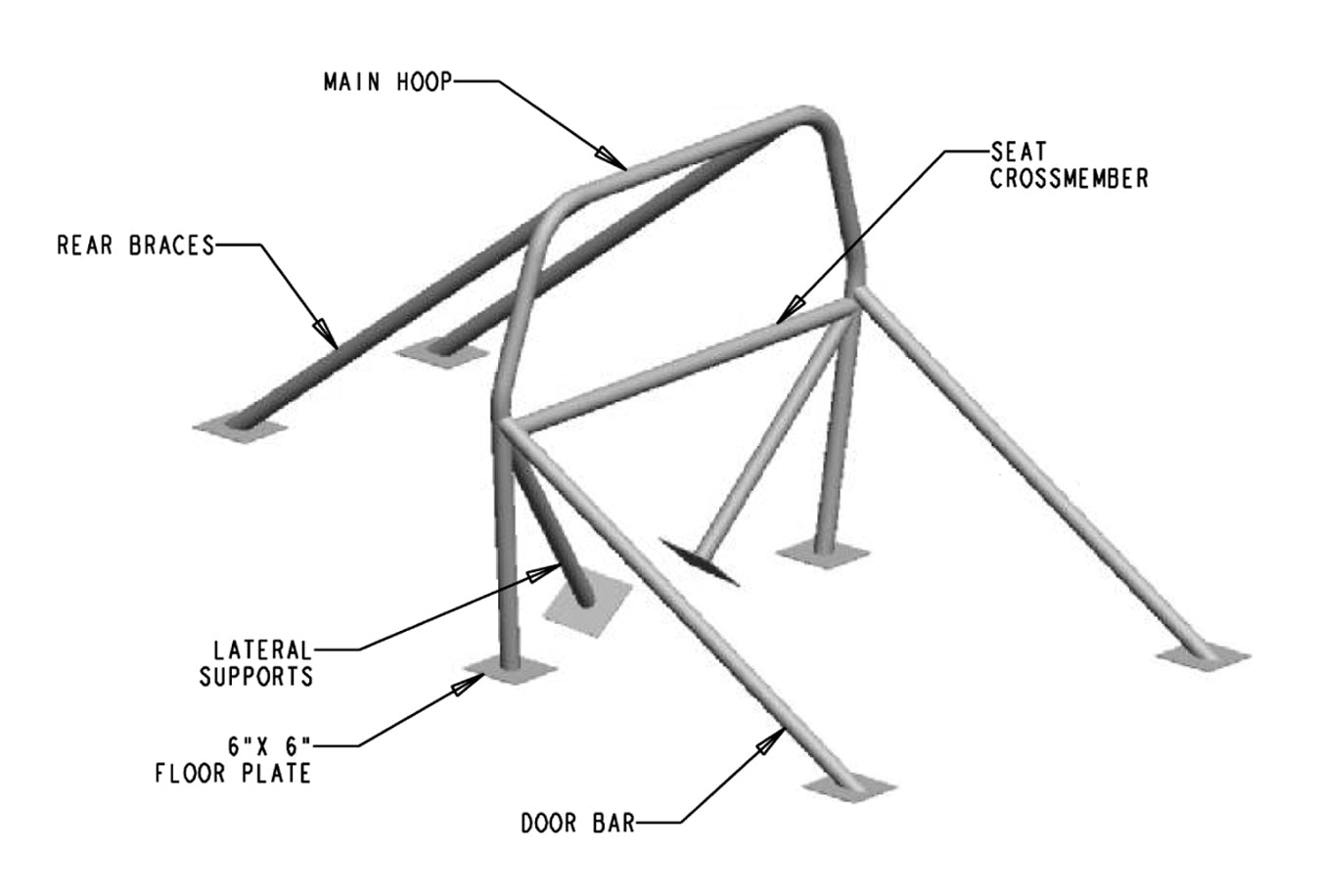

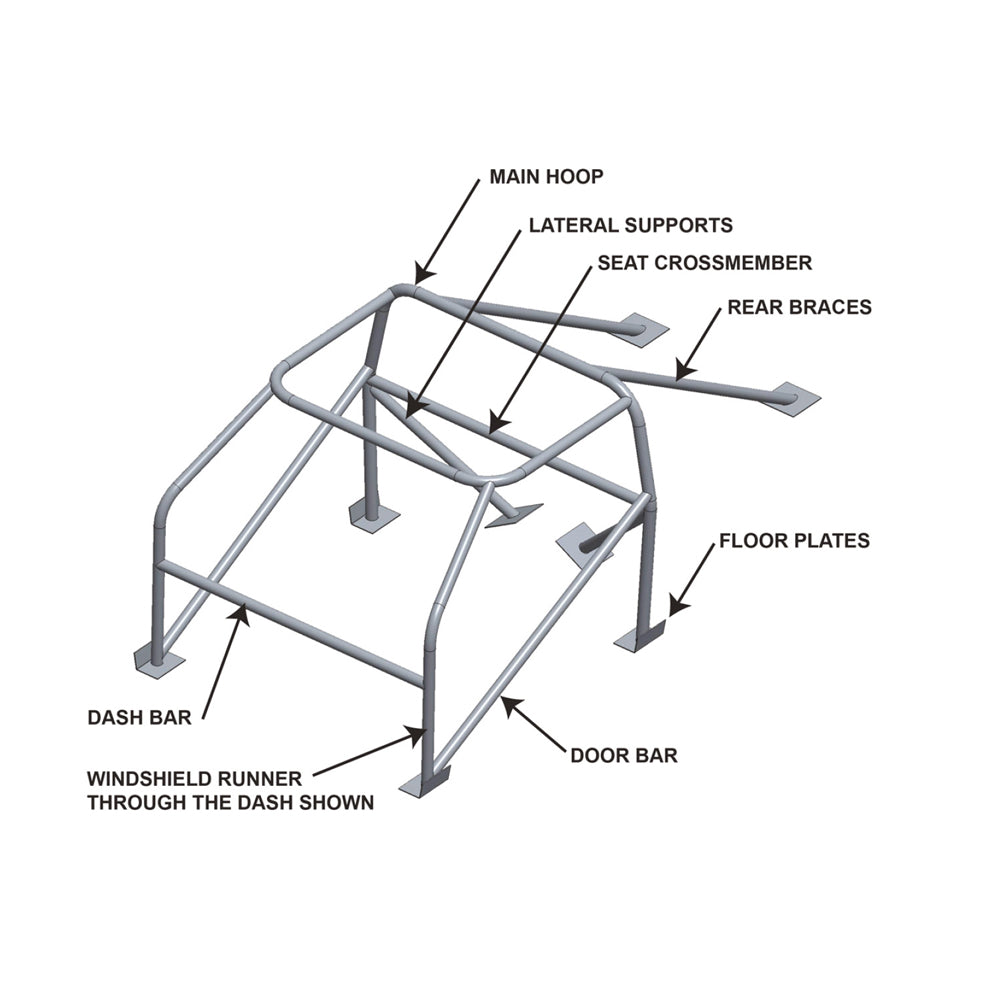

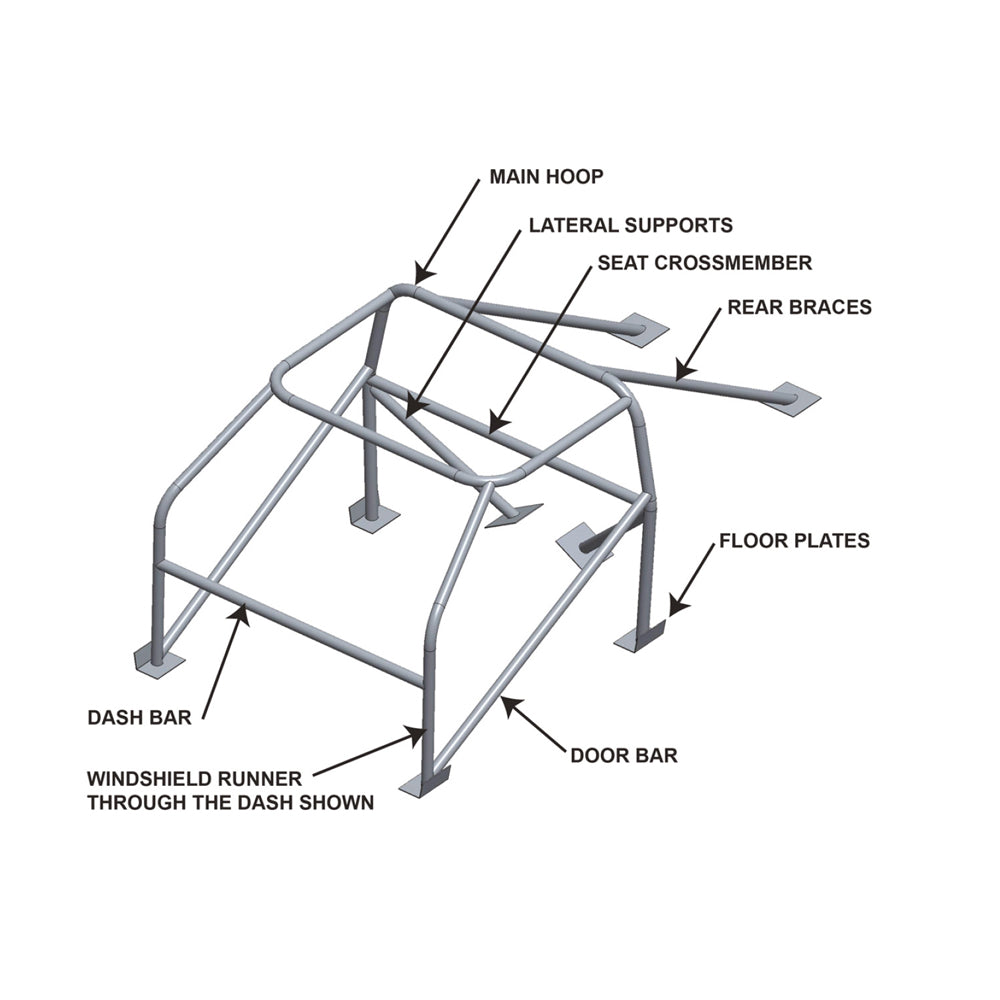

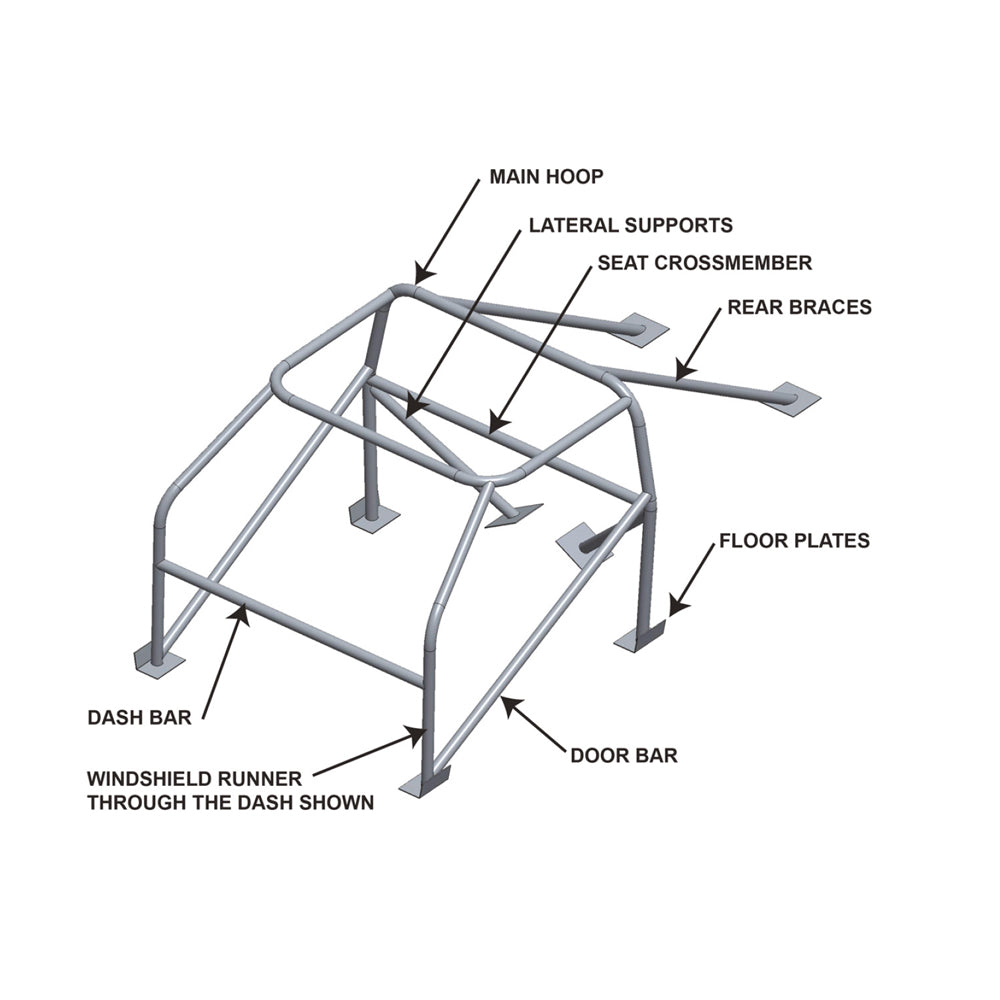

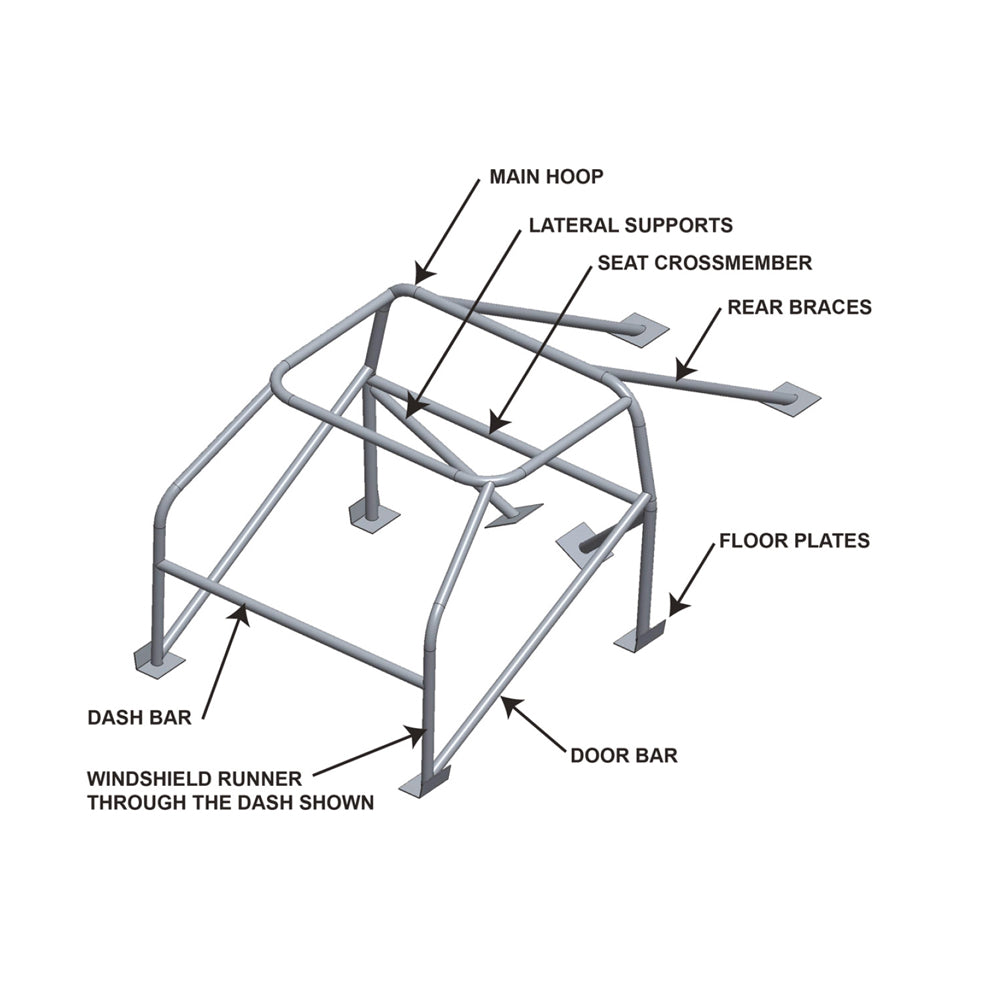

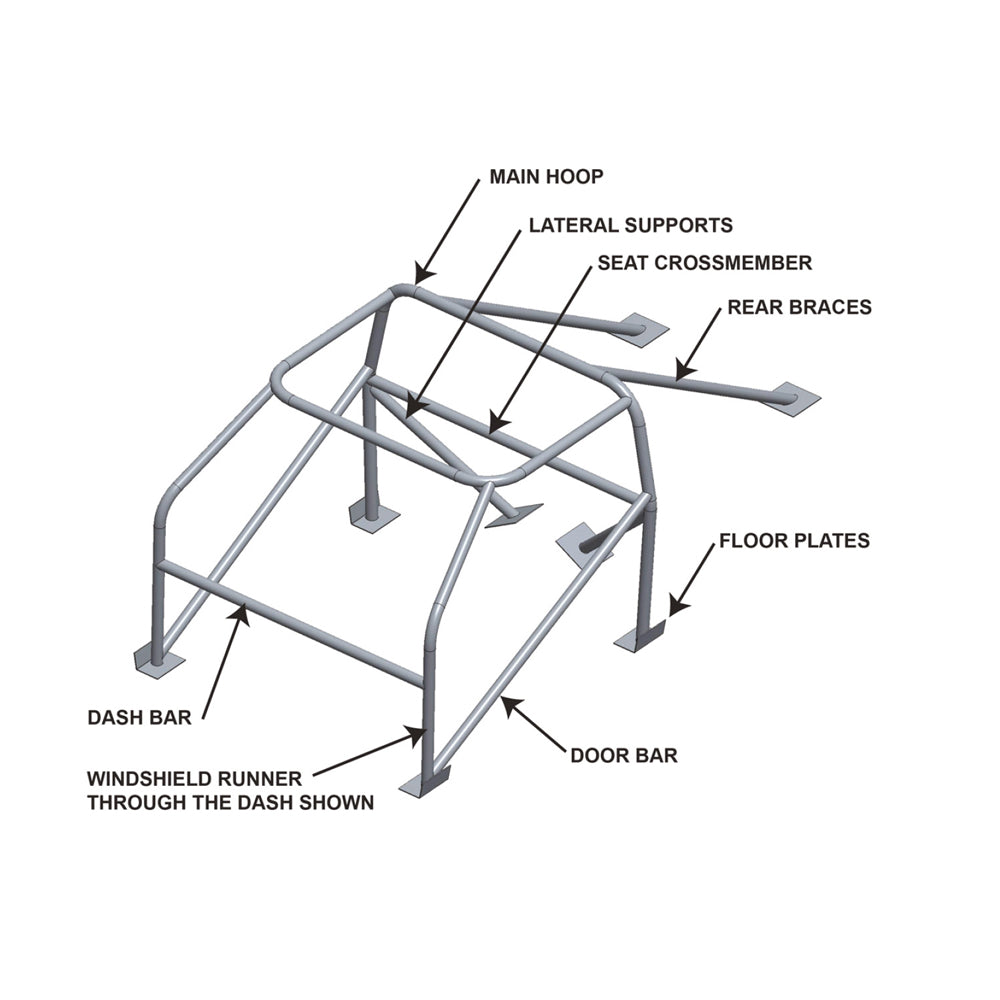

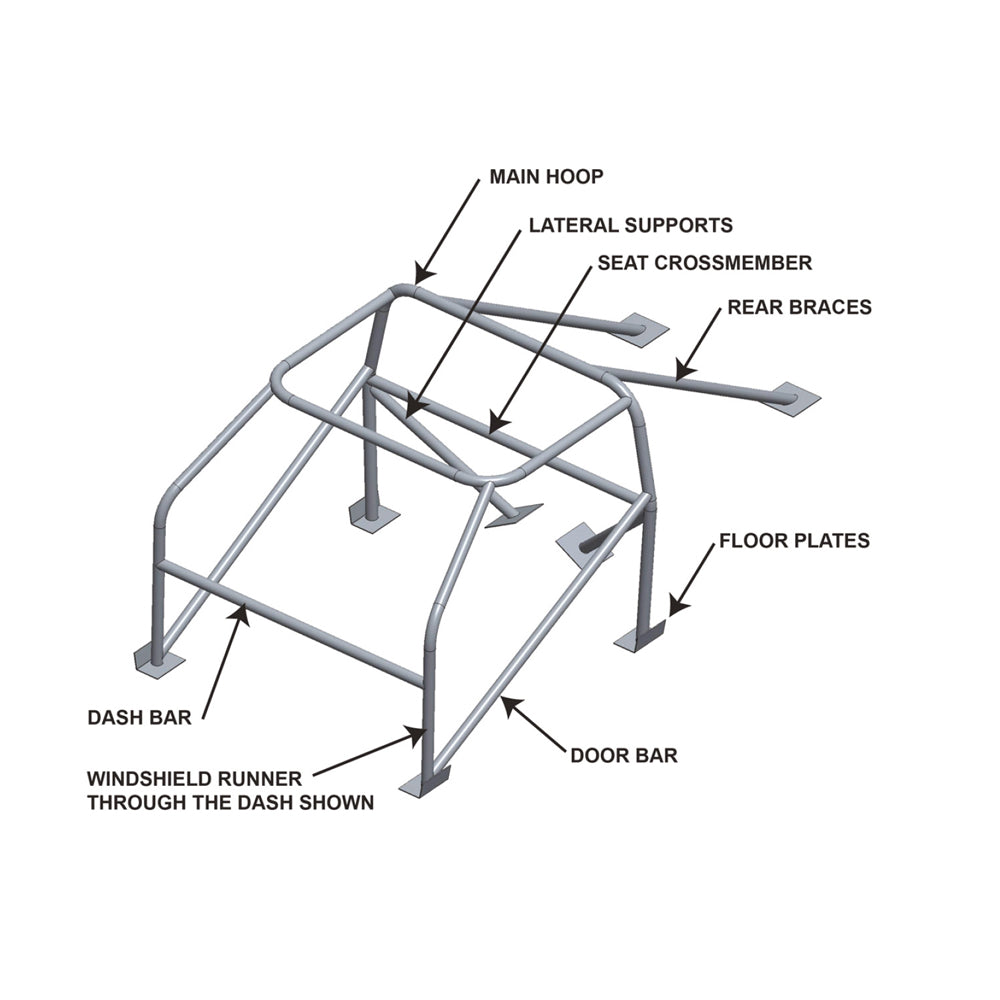

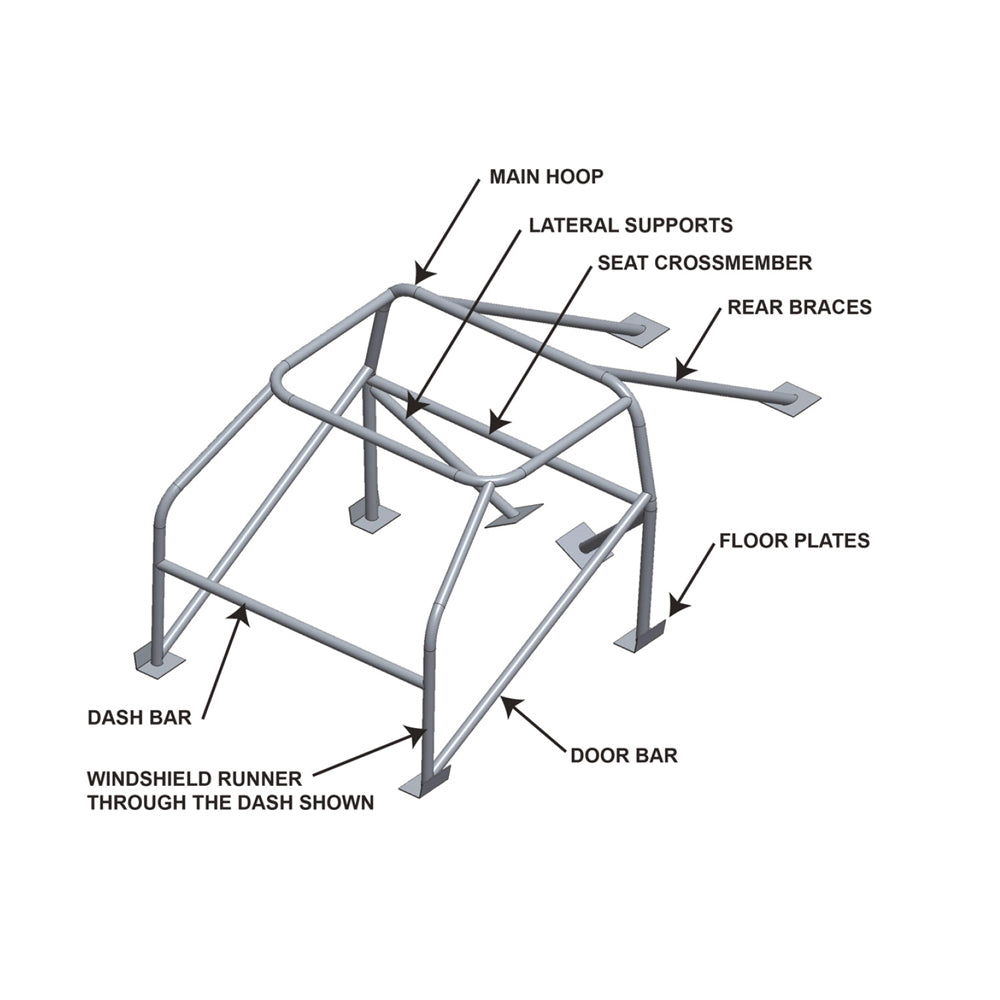

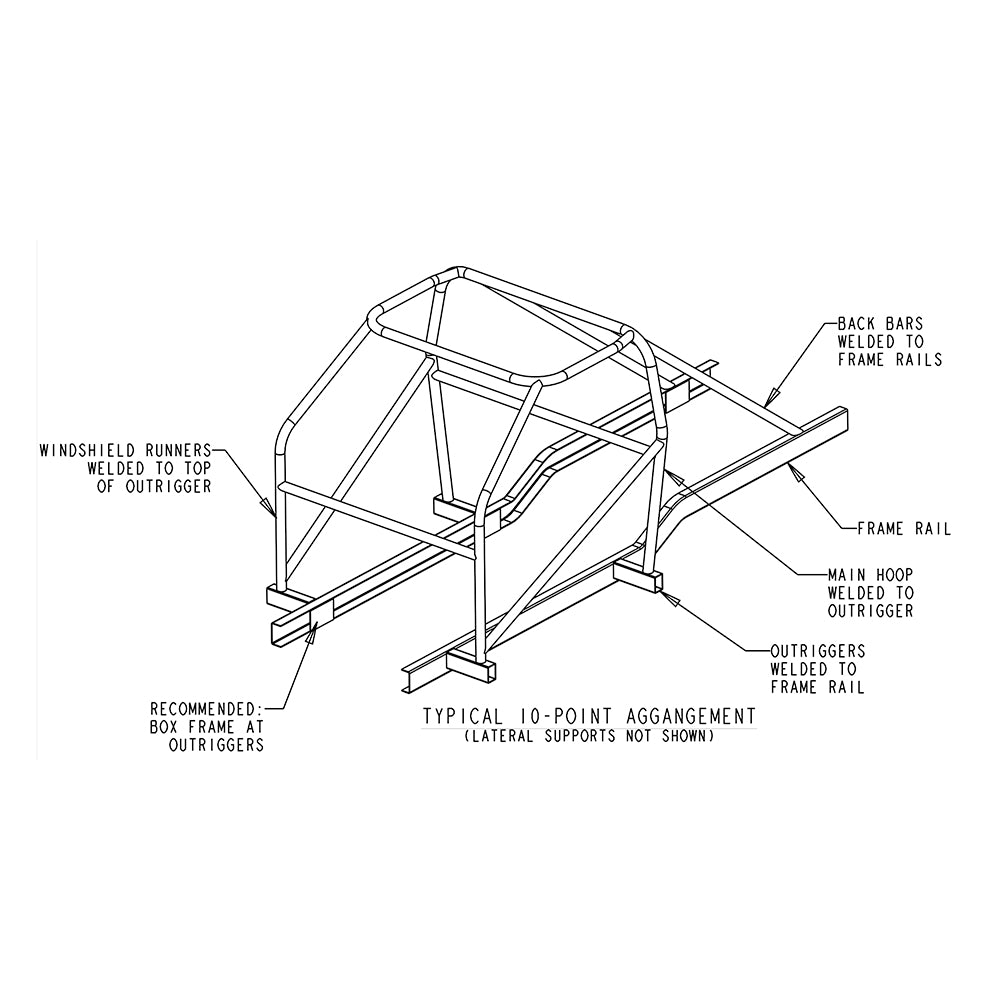

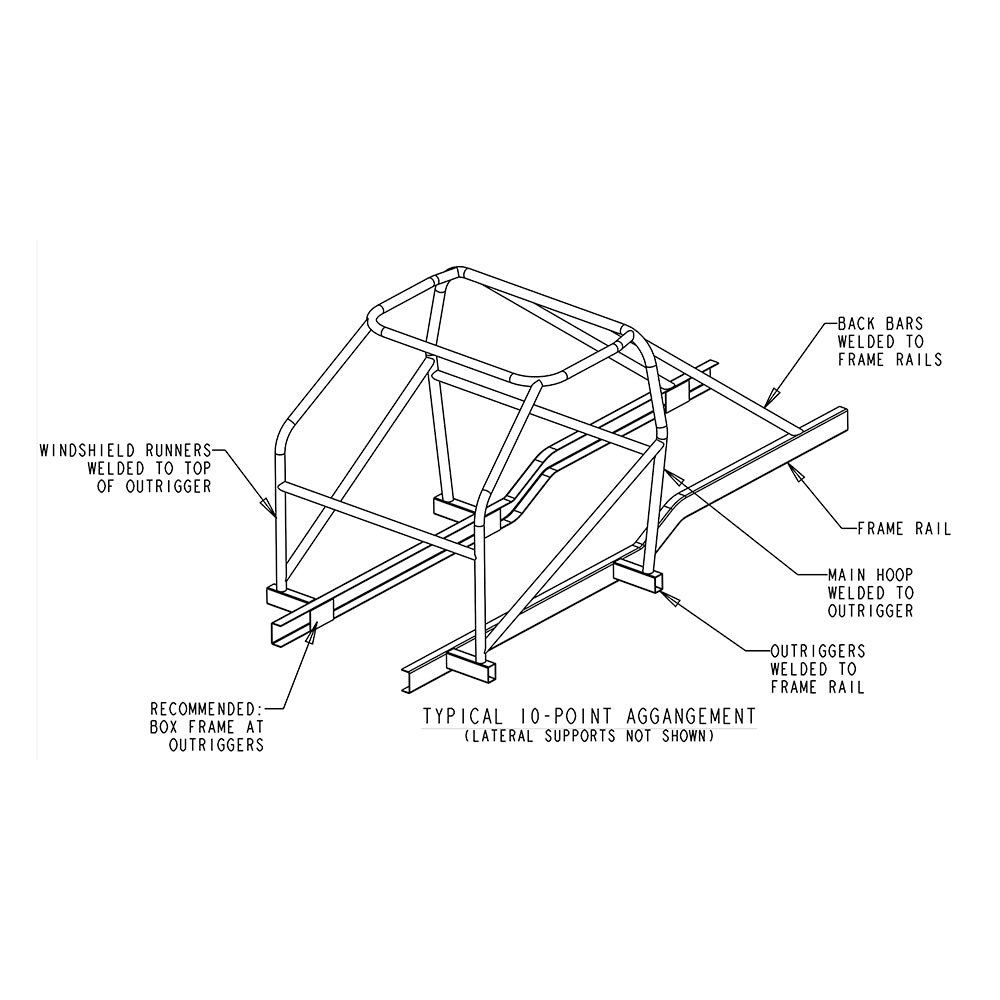

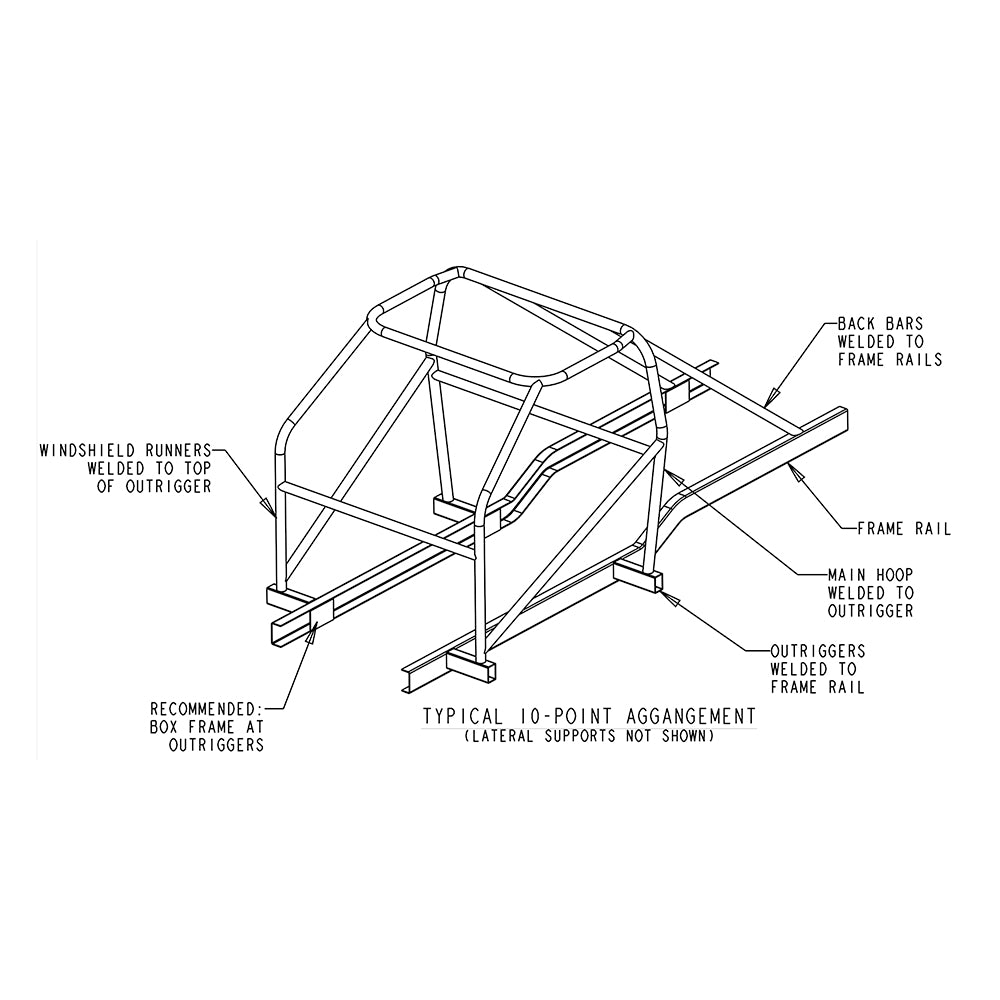

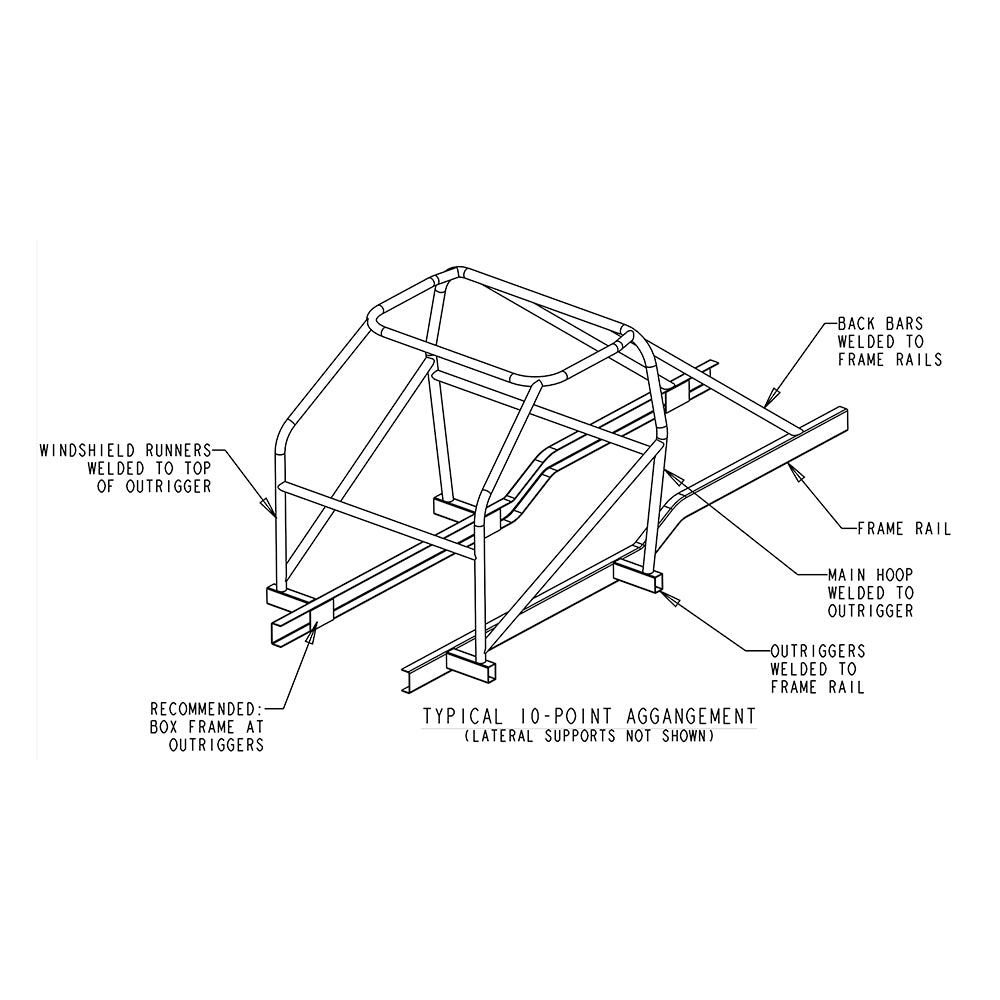

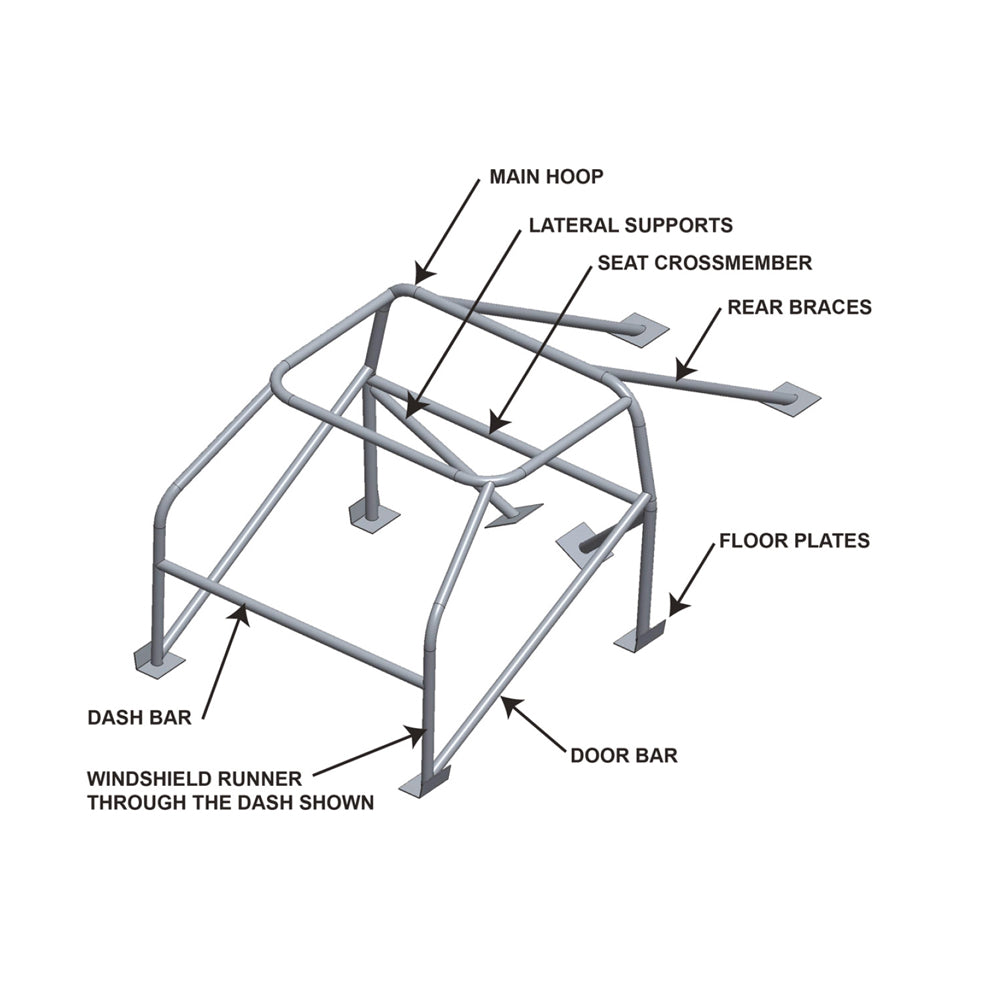

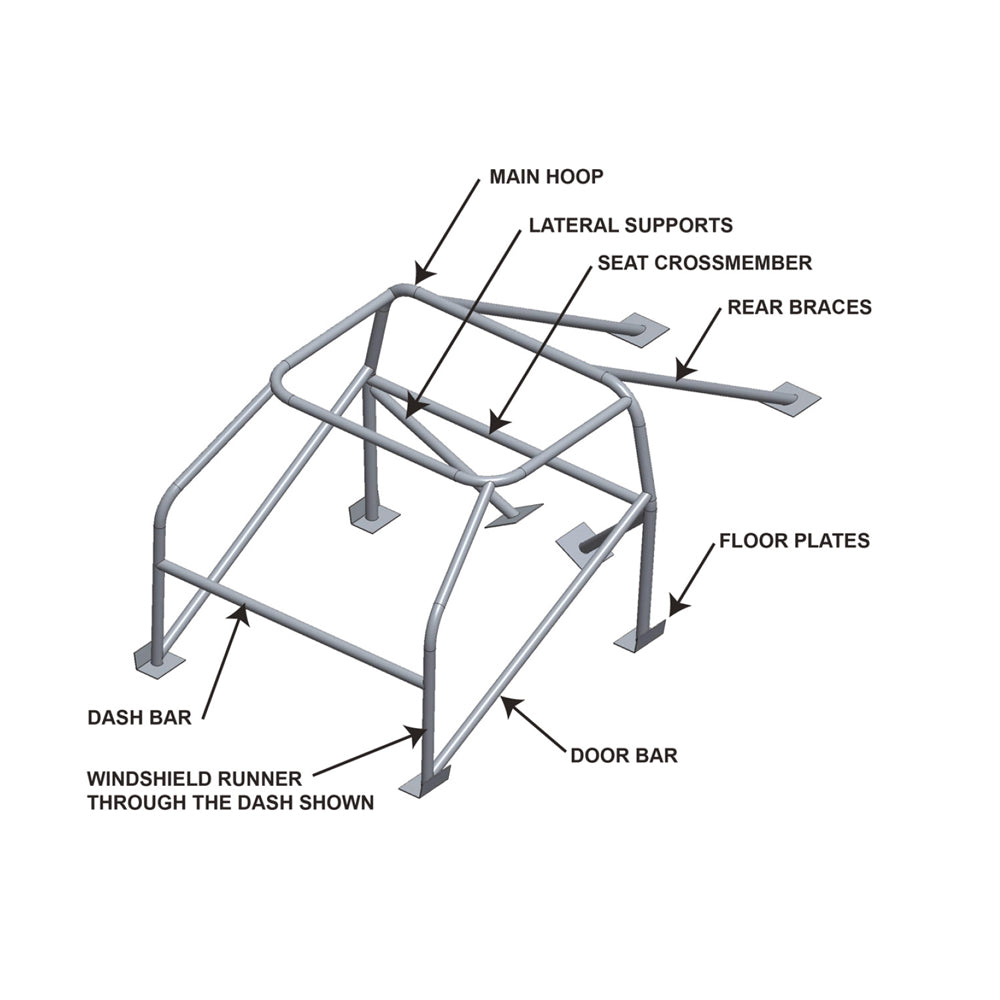

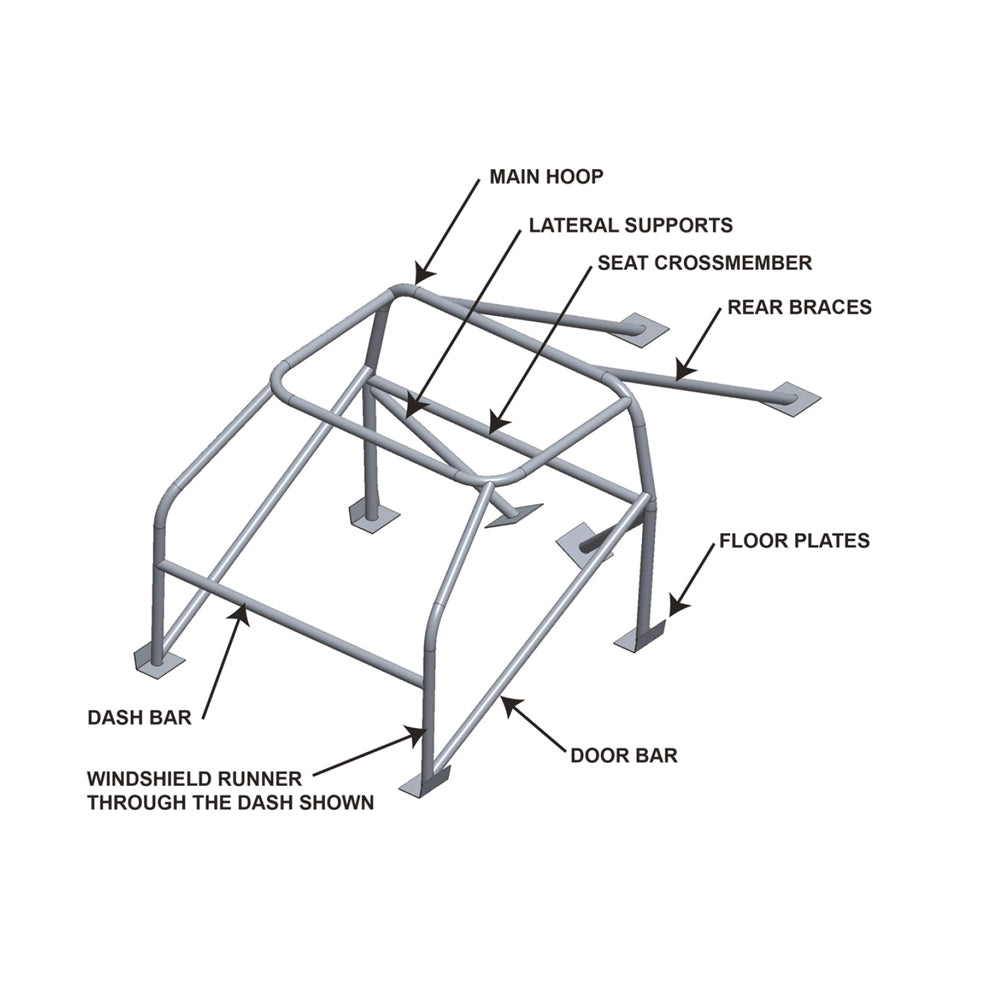

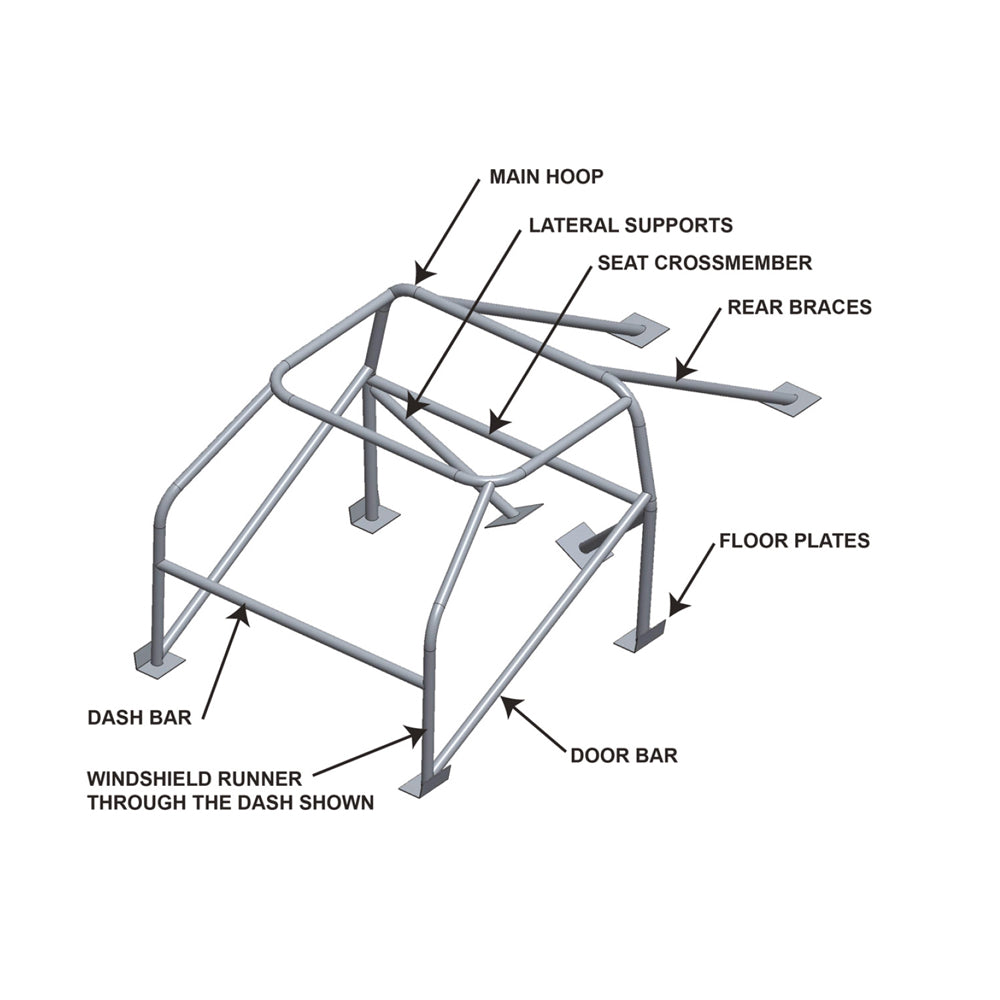

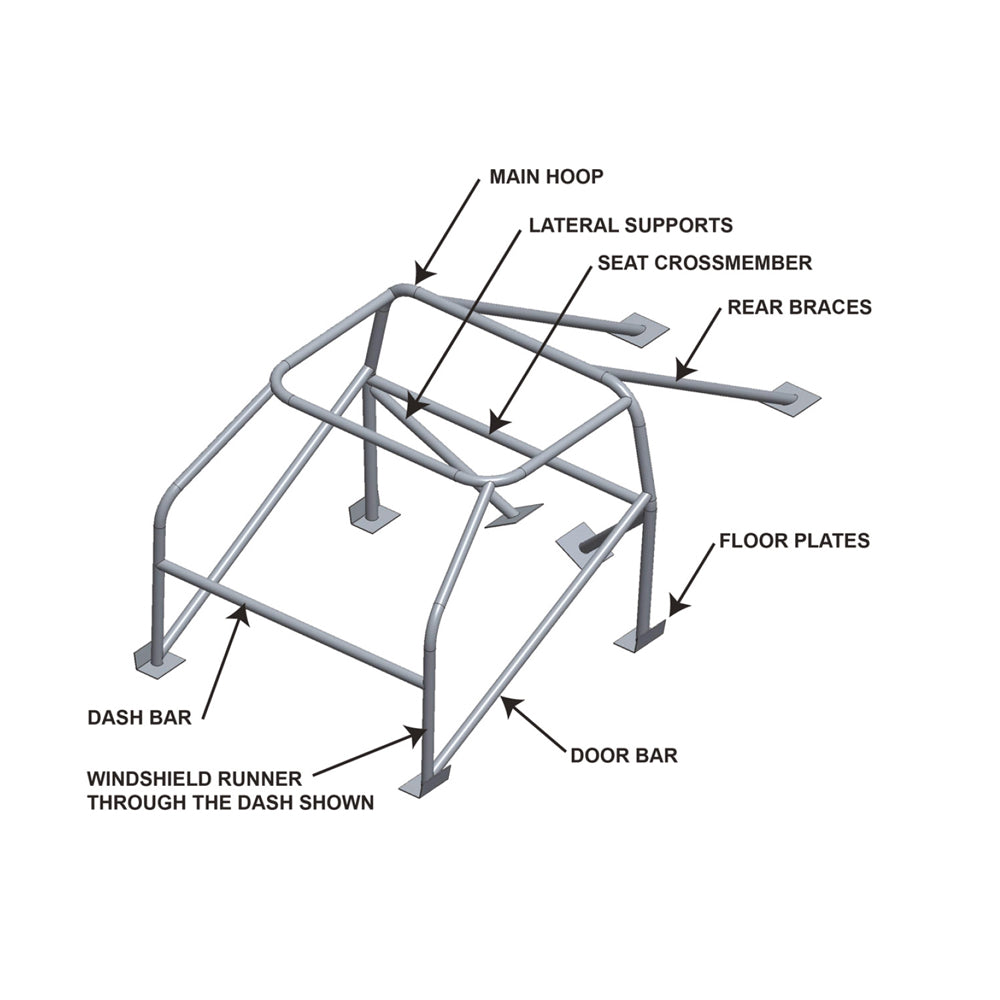

As a safety device, the main hoop of the cage protects the driver from impact. The rear braces and side bars tie the main hoop and chassis together to strengthen the car.

From a performance standpoint, the cage will improve your car's traction. Performance will also be greatly enhanced reducing chassis flex and increase the useful life of your car.

S&W Performance Group Roll Bars & Roll Cages Feature Notched Tube Ends for Ease of Installation.

Material Types

S&W Performance Group Recommends EWS (Electric Welded Seem) Mild Steel or 4130 Chromoly Steel for Drag Racing.

EWS Mild Steel

EWS stands for Electric Welded Seem and are made with .134″ wall thickness.

EWS 8 Point Roll Bars are NHRA & IHRA APPROVED 10 seconds 1/4 mile e.t. and slower

EWS 10 Point Roll Cages are NHRA & IHRA APPROVED 8.50 seconds 1/4 mile e.t. and slower

S&W Performance Group recommends MIG welding for EWS Roll Bars & Roll Cages.

4130 Chromoly Steel

4130 Chromoly Steel Roll Bars & Roll Cages are designed to be both lighter and stronger.

4130 Chromoly 8 Point Roll Bars are NHRA & IHRA APPROVED 10 seconds 1/4 mile e.t. and slower

4130 Chromoly 10 Point Roll Cages are NHRA & IHRA APPROVED 8.50 seconds 1/4 mile e.t. and slower

TIG welding is REQUIRED for 4130 Chromoly Steel Roll Bars & Roll Cages.